The Basic Principles Of DTF Transfer

The Basic Principles Of DTF Transfer

Blog Article

No Weeding Required: contrary to vinyl or other transfer solutions, DTF doesn’t need the laborous task of hunting down excess substance. the look is printed right on the Unique movie, plus the transfer procedure is straightforward and cleanse.

effects of design and style measurement on material drape: Printing a substantial design on a fabric can affect its overall flexibility and drape. to take care of The material’s purely natural movement, you might want utilizing lesser prints for the shirts and sweats.

Direct-to-movie transfers may provide speedier turnaround times when compared to traditional display screen printing. classic monitor printing requires a great deal of setup time and labor, which can result in for a longer period guide periods.

Furthermore, be sure to use substantial-quality elements and even perhaps conduct a check press with an extra transfer on a little place just before making use of a bigger style to ensure right temperature, strain, and transfer top quality.

develop your horizons and examine new possibilities in textile printing with our innovative DTF printers.

This part sets the muse for comprehension how you can print DTF transfers very easily with Do-it-yourself procedures.

Any excess powder is taken off by shaking or tapping the film. Often, Particular gear known as shakers is Utilized in this method to make sure the powder is laid evenly all through the film.

never use fabric softener, do not bleach or dry cleanse, and dry on a low setting. Your DTF transfers could be washed regularly or within-out, although the latter is usually recommended.

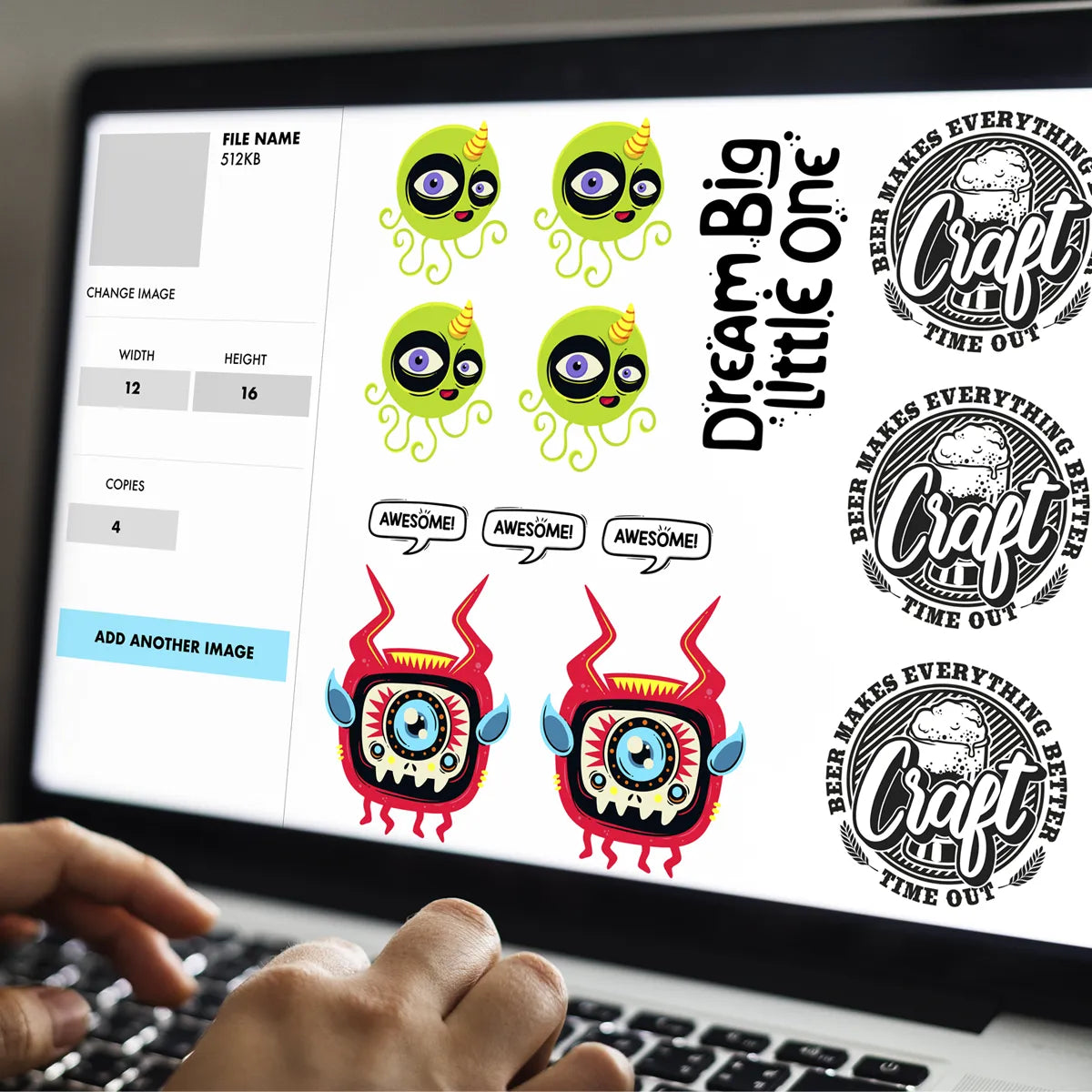

You may use All set-designed layouts or produce tailor made designs in the digital natural environment making use of structure software package. Transfer your style and design towards the DTF printer to accomplish the printing.

at the time you get and approve your proof from [email protected], we are going to quickly move your transfer into output. it is going to acquire one-three business enterprise days of output right before your transfers are more info delivered out. much larger orders may hold off this creation time.

However, with the opportunity to print on a wide range of supplies with no need pre-treatment method, DTF transfers absolutely are a game-changer for firms of all measurements.

3. implementing the Adhesive: A powder adhesive is placed on the soaked ink just after printing. This adhesive lets the design to bond with The material when warmth pressed.

DTF printer that prints the design onto a transfer sheet. This sheet is then wanting to push on to a garment utilizing heat and strain, generally by using a heat press device .

Next, you should feed your design and style to the DTF printer. The DTF printer makes use of inkjet know-how to transfer the design onto a PET film.

Report this page